Summary

Radiative heat transfer between two or more surfaces can be approximated using the total, normal emissivity. This article provides empirically determined total normal emissivities for a number of materials including metals, metal oxides, common building materials and paints.

Definitions

| : | Emissivity (dimensionless) | |

| : | Absorptivity of a material (dimensionless) | |

| : | A property of the normal direction |

Introduction

Treatment of radiative emission can be simplified by assuming that the emissivity is spectrally independent i.e. emissivity is constant with respect to wavelength. In this case the simplified emissivity is called the directional emissivity and represents the ‘spectral average’ of emission and hence the common name of this assumption; the grey surface approximation (wavelength of radiation determines colour and the ‘average’ of all colours is grey).

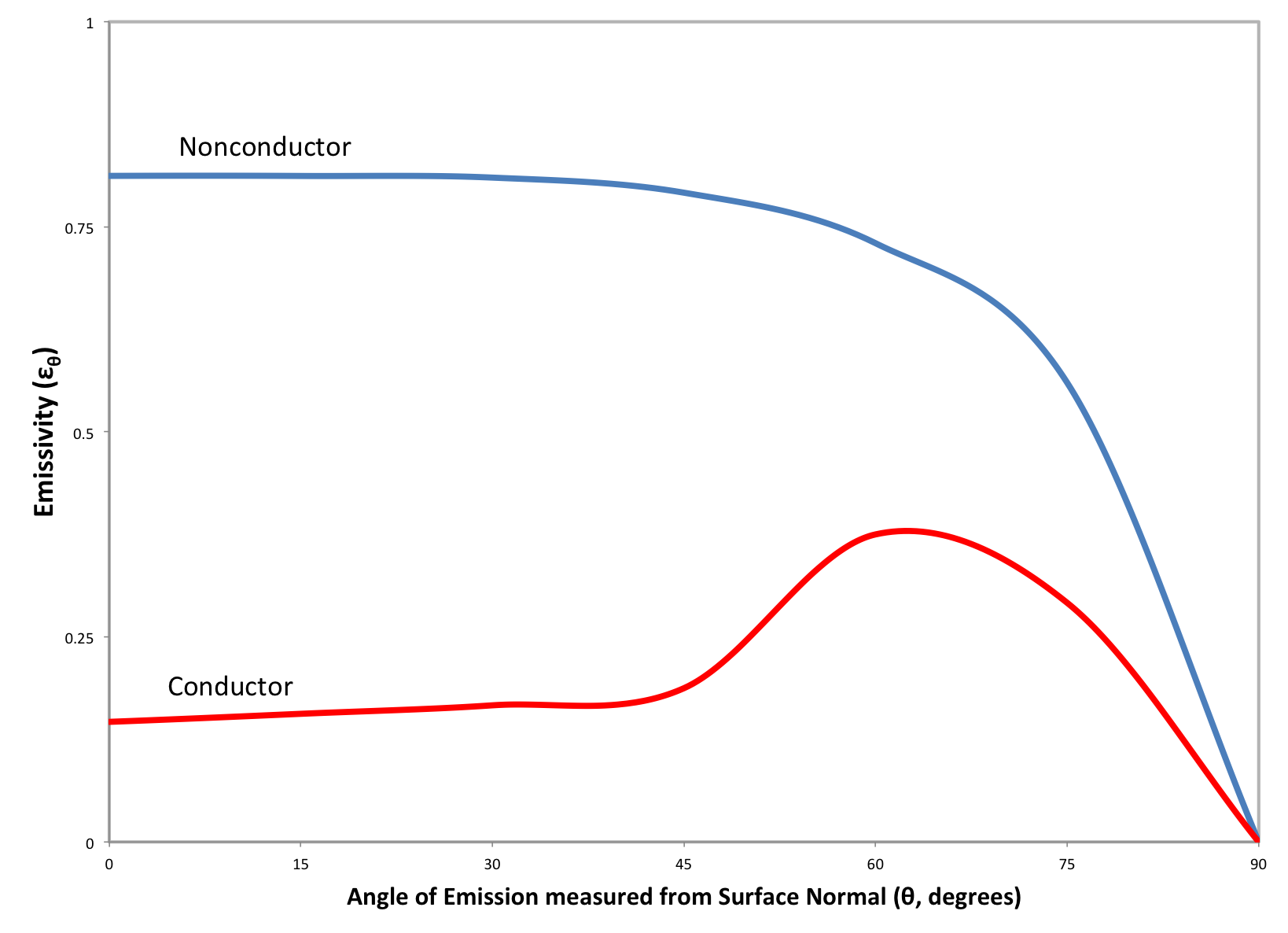

Although the total emissivity is averaged over all wavelengths it still maintains directional dependence which is a source of complexity in radiative heat transfer calculations. However, as described in the emissivity article and shown in the figure below, both conductors and non-conductors alike can be reasonably approximated using the emissivity in the normal direction.

In the subsequent sections the typical total, normal emissivities are listed for a range of materials.

Metals and Metallic Oxides

| Material | Type | Temperature | Emissivity | Absorptivity |

|---|---|---|---|---|

| Alumina | Flame-sprayed | -25 | 0.80 | 0.28 |

| Aluminum | Vacuum-deposited | 20 | 0.025 | 0.10 |

| Anodized | 20 | 0.84 | 0.14 | |

| Hard-anodized | -25 | 0.84 | 0.92 | |

| Polished | 20 | 0.03 | 0.09 | |

| Highly polished plate, 98.3% pure | 225 - 575 | 0.039 - 0.057 | - | |

| Commercial sheet | 100 | 0.09 | - | |

| Rough polish | 100 | 0.18 | - | |

| Rough plate | 40 | 0.055 - 0.07 | - | |

| Oxidized at 600°C | 200 - 600 | 0.11 - 0.19 | - | |

| Heavily oxidized | 95 - 500 | 0.20 - 0.31 | - | |

| Surface roofing | 38 | 0.216 | - | |

| Foil, As received | 20 | 0.04 | 0.15 | |

| Foil, Bright dipped | 20 | 0.025 | 0.10 | |

| Antimony | Polished | 35 - 260 | 0.28 - 0.31 | - |

| Beryllium | Typical | 150 | 0.18 | 0.77 |

| 370 | 0.21 | - | ||

| 600 | 0.30 | - | ||

| Anodized | 150 | 0.90 | - | |

| 370 | 0.88 | - | ||

| 600 | 0.82 | - | ||

| Bismuth | Bright | 75 | 0.34 | - |

| Brass | Polished | 40 - 315 | 0.096 - 0.10 | - |

| Rolled plate, natural surface | 22 | 0.06 | - | |

| Hard rolled plate, polished | 21 | 0.038 | - | |

| Dull plate | 50 - 350 | 0.22 | - | |

| Rubbed with coarse emery | 22 | 0.20 | - | |

| Oxidized by heating at 600°C | 200 - 600 | 0.61 - 0.59 | - | |

| Chrome | Black plated | 20 | 0.09 | 0.87 |

| Chromium | Polished | 40 - 1100 | 0.08 - 0.36 | - |

| Copper | Electroplated | 20 | 0.03 | 0.47 |

| Carefully polished electrolytic copper | 80 | 0.018 | - | |

| Polished | 20 | 0.03 | 0.18 | |

| 115 | 0.023 | - | ||

| Commercial, scraped shiny | 22 | 0.072 | - | |

| Plate, oxidised | 225 | 0.78 | - | |

| Plate, heated at 600°C | 200 - 600 | 0.57 | - | |

| Cuprous oxide | 800 - 1100 | 0.66 - 0.54 | - | |

| Molten copper | 1075 - 1275 | 0.16 - 0.13 | - | |

| Tarnished | 20 | 0.75 | 0.65 | |

| Gold | Pure, highly polished | 225 - 625 | 0.018 - 0.035 | - |

| Inconel X | Oxidized | -25 | 0.71 | 0.90 |

| Iron | Cast, newly turned | 22 | 0.435 | - |

| Cast, turned | 882 - 988 | 0.60 - 0.70 | - | |

| Cast, polished | 200 | 0.21 | - | |

| Cast, oxidised at 872 K | 199 - 599 | 0.64 - 0.78 | - | |

| Cast, strongly oxidised | 38 - 249 | 0.95 | - | |

| Electrolytic, highly polished | 177 - 227 | 0.052 - 0.064 | - | |

| Electrolytic, smooth oxidised | 227 - 527 | 0.78 - 0.82 | - | |

| Freshly emeried | 20 | 0.242 | - | |

| Ingot, rough | 499 - 1199 | 0.85 - 0.89 | - | |

| Ingot, rough, oxidised | 927 - 1117 | 0.87 - 0.95 | - | |

| Molten cast iron | 1299 - 1399 | 0.29 | - | |

| Molten mild steel | 1599 - 1797 | 0.28 | - | |

| Oxide | 499 - 1199 | 0.85 - 0.89 | - | |

| Oxidised | 100 | 0.736 | - | |

| Plate, completely rusted | 20 | 0.685 | - | |

| Polished | 427 - 1027 | 0.144 - 0.377 | - | |

| Sheet, smooth | 899 - 1038 | 0.55 - 0.60 | - | |

| Steel casting, polished | 771 - 1038 | 0.52 - 0.56 | - | |

| Steel sheet ground | 938 - 1099 | 0.55 - 0.61 | - | |

| Steel sheet oxidised | 22 | 0.657 | - | |

| Steel sheet, rough oxide layer | 24 | 0.80 | - | |

| Steel plate rough | 38 - 371 | 0.94 - 0.97 | - | |

| Steel oxidised at 872 K | 199 - 599 | 0.79 | - | |

| Wrought iron, highly polished | 38 - 249 | 0.28 | - | |

| Wrought, dull oxidised | 21 - 360 | 0.94 | - | |

| Lead | Pure (99.96%), unoxidized | 125 - 225 | 0.057 - 0.075 | - |

| Gray oxidized | 25 | 0.281 | - | |

| Oxidized at 150°C | 200 | 0.63 | - | |

| Oxidized at 200°C | 200 | 0.03 | - | |

| Magnesium | Polished | 35 - 260 | 0.07 - 0.13 | - |

| Magnesium oxide | Typical | 275 - 825 | 0.55 - 0.20 | - |

| 900 - 1705 | 0.20 | - | ||

| Mercury | Typical | 0 - 100 | 0.09 - 0.12 | - |

| Molybdenum | Polished | 35 - 260 | 0.05 - 0.08 | - |

| 540 - 1370 | 0.10 - 0.18 | - | ||

| 2750 | 0.29 | - | ||

| Filament | 727 - 2593 | 0.096 - 0.292 | - | |

| Monel | Metal oxidised | 200 - 600 | 0.41 - 0.46 | - |

| Nickel | Electroplated | 20 | 0.03 | 0.22 |

| Electroplated on polished iron and polished | 23 | 0.045 | - | |

| Electroplated on pickled iron, unpolished | 20 | 0.11 | - | |

| Polished | 100 - 327 | 0.072 - 0.087 | - | |

| Wire | 187 - 1007 | 0.096 - 0.186 | - | |

| Technically pure, polished | 227 - 327 | 0.07 - 0.087 | - | |

| Plate, oxidised by heating to 872 K | 200 - 600 | 0.37 - 0.48 | - | |

| Oxide | 649 - 1254 | 0.59 - 0.86 | - | |

| Oxide, Black plated | 20 | 0.08 | 0.92 | |

| Nickel Alloys | Chromonickel | 52 - 1035 | 0.64 - 0.76 | - |

| Nickelin, grey oxidised | 21 | 0.262 | - | |

| KA-28 alloy, rough brown, after heating | 216 - 490 | 0.44 - 0.36 | - | |

| KA-28 alloy, after heating at 800 K | 216 - 527 | 0.62 - 0.73 | - | |

| NCT 3 alloy, oxidised from service | 216 - 527 | 0.90 - 0.97 | - | |

| NCT 6 alloy, oxidised from service | 271 - 563 | 0.89 - 0.82 | - | |

| Platinum | Pure, polished | 225 - 625 | 0.054 - 0.104 | - |

| Strip | 927 - 1627 | 0.12 - 0.17 | - | |

| Filament | 27 - 1327 | 0.036 - 0.192 | - | |

| Wire | 227 - 1327 | 0.073 - 0.182 | - | |

| Silver | Polished, pure | 227 - 625 | 0.0198 - 0.0324 | - |

| Polished | 37 - 371 | 0.0221 - 0.0312 | - | |

| Stainless steel | Typical polished | 20 | 0.60 | 0.37 |

| Typical dull | 20 | 0.21 | 0.50 | |

| Type 312, heated 300 h at 260°C | 95 - 425 | 0.27 - 0.32 | - | |

| Type 301 with Armco black oxide | -25 | 0.75 | 0.89 | |

| Type 410, heated to 700°C in air | 35 | 0.13 | 0.76 | |

| Type 303, sandblasted | 95 | 0.42 | 0.68 | |

| Tantalum | Filament | 1327 - 2999 | 0.194 - 0.31 | - |

| Tin | Bright tinned iron sheet | 25 | 0.043 - 0.064 | - |

| Titanium | 75A | 95 - 425 | 0.10 - 0.19 | - |

| 75A, oxidized 300 h at 450°C | 35 - 425 | 0.21 - 0.25 | 0.80 | |

| Anodized | -25 | 0.73 | 0.51 | |

| Tungsten | Filament, aged | 27 - 3300 | 0.032 - 0.35 | - |

| Filament | 3315 | 0.39 | - | |

| Zinc | Pure, polished | 225 - 325 | 0.045 - 0.053 | - |

| Oxidised by heating to 672 K | 399 | 0.11 | - | |

| Galvanised sheet | 100 | 0.21 | - | |

| Galvanized sheet iron, grey oxidised | 24 | 0.276 | - | |

| Galvanized sheet iron, fairly bright | 28 | 0.228 | - |

Other Materials

| Material | Type | Temperature | Emissivity | Absorptivity |

|---|---|---|---|---|

| Material | Type | Temperature | Total, Normal Emittance | Solar Absorptance |

| Asbestos | Board | 24 | 0.96 | - |

| Paper | 35 - 370 | 0.93 - 0.94 | - | |

| Asphalt | Typical | 20 | 0.90 | 0.90 |

| Brick | Red, rough | 21 | 0.93 | 0.63 |

| Silica, unglazed | 1002 | 0.8 | - | |

| Silica, glazed, rough | 1202 | 0.85 | - | |

| Grog, glazed | 1202 | 0.75 | - | |

| Carbon | Graphitized | 100 - 320 | 0.76 - 0.75 | - |

| Graphitized | 320 - 500 | 0.75 - 0.71 | - | |

| T-carbon | 127 - 627 | 0.81 - 0.79 | - | |

| Candle soot | 98 - 271 | 0.952 | - | |

| Graphite, pressed, filed surface | 250 - 510 | 0.98 | - | |

| Lampblack-water-glass coating | 100 - 183 | 0.957 - 0.952 | - | |

| Lampblack, thin layer on iron plate | 21 | 0.927 | - | |

| Lampblack, thick coat | 20 | 0.967 | - | |

| Lampblack, 0.08 mm or thicker | 38 - 371 | 0.945 | - | |

| Filament | 1038 - 1404 | 0.526 | - | |

| Concrete | Typical | 20 | 0.88 | 0.60 |

| Enamel | Snow white | 23 | 0.906 | - |

| White fused on iron | 19 | 0.897 | - | |

| Glass | Smooth | 22 | 0.937 | - |

| Pyrex, lead, and soda | 260 - 540 | 0.95 - 0.85 | - | |

| Gypsum | 0.5 mm thick on blackened plate | 20 | 0.903 | - |

| Human Skin | Caucasian | 20 | 0.97 | 0.62 |

| Marble | Light grey, polished | 22 | 0.931 | - |

| White | 20 | 0.95 | 0.46 | |

| Oil Layer on polished nickel | 0.025 mm oil | 0.27 | - | |

| 0.050 mm oil | 0.46 | - | ||

| 0.125 mm oil | 0.72 | - | ||

| Thick oil layer | 0.82 | - | ||

| Oil layer on aluminium foil | 1 coat of oil | 100 | 0.561 | - |

| 2 coats of oil | 100 | 0.574 | - | |

| Paint, Lacquer & Varnish | Aluminium paint | 100 | 0.27 - 0.67 | - |

| Aluminium paint after heating to 600 K | 149 - 349 | 0.35 | - | |

| Aluminium lacquer | 21 | 0.39 | - | |

| Black paint | 20 | 0.97 | 0.97 | |

| Parson’s optical black | -25 | 0.95 | 0.975 | |

| Black shiny lacquer sprayed on iron | 25 | 0.875 | - | |

| Black shiny shellac on tinned iron sheet | 21 | 0.821 | - | |

| Black matt shellac | 77 - 147 | 0.91 | - | |

| Black lacquer | 38 - 93 | 0.80 - 0.95 | - | |

| Black matt lacquer | 38 - 93 | 0.96 - 0.98 | - | |

| Black silicone | -25 - 750 | 0.93 | 0.94 | |

| Black enamel paint | 95 - 425 | 0.81 - 0.80 | - | |

| Black epoxy paint | -25 | 0.89 | 0.95 | |

| Oil paints | 100 | 0.92 - 0.96 | - | |

| White lacquer | 38 - 93 | 0.80 - 0.95 | - | |

| White Paint | 20 | 0.93 | 0.14 | |

| Paper | Pasted on tinned iron plate | 19 | 0.924 | - |

| Pasted on rough iron plate | 19 | 0.929 | - | |

| Pasted on black lacquered plate | 19 | 0.944 | - | |

| Roofing | 21 | 0.91 | - | |

| Plaster | Lime, rough | 10 - 88 | 0.91 | - |

| Porcellain | Glazed | 22 | 0.924 | - |

| Quartz | Rough, fused | 21 | 0.932 | - |

| Refractory materials | Poor radiators | 600 - 1000 | 0.65 - 0.75 | - |

| Good radiators | 600 - 1000 | 0.80 - 0.90 | - | |

| Rubber | Hard, glossy plate | 23 | 0.945 | - |

| Soft, grey, rough | 25 | 0.859 | - | |

| Serpentine | Polished | 23 | 0.900 | - |

| Silica | Sintered, powdered, fused silica | 35 | 0.84 | 0.08 |

| Silicon carbide | Typical | 150 - 650 | 0.83 - 0.96 | - |

| Snow | Typical | 0 | 0.97 | 0.28 |

| Water | Typical | 0 - 100 | 0.95 - 0.963 | - |

| Wood | Oak, planed | 21 | 0.895 | - |

Further Reading

- Chemical Engineering Volume 1, Sixth Edition: Fluid Flow, Heat Transfer and Mass Transfer

- Heat Transfer Handbook

- Heat Transfer A Practical Approach

- Radiative Heat Transfer, Third Edition

Article Tags